S15C : Medium Carbon Steel

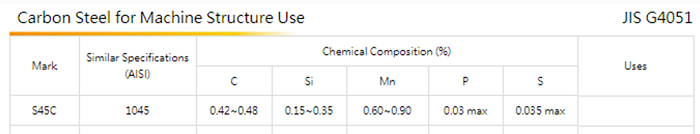

* Standard : JIS G4051 - 2009

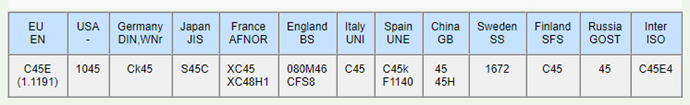

* Equivalent Grades :

Medium carbon steel is a kind of carbon steel which has 0.42%~0.48% of carbon content.

Medium carbon steel is a kind of carbon steel which has 0.42%~0.48% of carbon content.

Applications requiring strength and impact resistance of the component, because of its high carbon content, therefore, have a higher tensile strength, ductility and wear resistance, but is not suitable for welding or forming.

This steel grade can be supplied in many standard shapes, including round, square, hexagonal, and plate. It generally applicative used in nuts and bolts, axles, rollers, springs, wires, wheel frames, rods, engine parts, stamping dies, hammers, lock washers/lock pin gaskets, turbine rotors, railway tracks, cylinder sleeves, hand tools, screws, railway wheels, gears, garden shears, etc.

* Shapes : Round, Hexagon, Flat, Square.

* Surface Finish : Hot Rolled, Cold drawn, Chamfered.

* Available size range :

|

Bar |

|

ØRound bars : 2mm ~ 60mm ØSquare bars : 3mm ~ 45mm ØFlat Bar : 3mm ~ 65mm ØHexagonal bars : 3mm ~ 50mm |

|

· Length : 2meter ~ 5.8 meter |

* Chemical Composition :

* Mechanical properties

(1) Material

Tensile strength (kgf/mm²): ≧58

Yield strength (kgf/mm²): ≧35

Elongation (%): ≧20

Cross section reduction rate (%): ≧45

Hardness (Hb): 167~229

(2) After heat treatment

Tensile strength (kgf/mm²): ≧70

Yield strength (kgf/mm²): ≧50

Elongation (%): ≧17

Cross section reduction rate (%): ≧45

Hardness (Hb): 201~294

* Conditions of heat treatment

· Annealing: 880℃ Furnace Cooling

· Normalization: 880~870℃ Air Cooling

· Hardening: 820~870℃ Water Cooling

· Tempering: 550~650℃ Rapid Cooling