SCM420 & SCM420H : Thép hợp kim

* Standard : JIS G4105-1979

* Equivalent Grades : GB 20CrMo, JIS SCM420, SCM420H, ASTM 4118, DIN 25CrMo4.

SCM420 are alloy steel with high hardenability, temper brittleness, well weldability, less cold cracking tendency, good machinability, and great cold plastic strain. SCM420 generally are used for the parts which need high wear resistance, such as gears, shafts, high-pressure pipes, all kinds of fasteners, and so on.

* Shapes : Round, Hexagon, Flat, Square, Profile.

* Surface Finish : Cold drawn, Hot rolled, Bright, Polished, Centerless Grinding (CG), Chamfered.

* Available size range :

|

Bar |

|

ØRound bars Cold drawn : 2mm ~ 55mm Hot Rlooed : 32mm ~ 90mm ØSquare bars : 3mm ~ 45mm ØFlat Bar : 3mm ~ 65mm ØHexagonal bars : 3mm ~ 50mm |

|

· Available Length : 2meter ~ 5.8 meter |

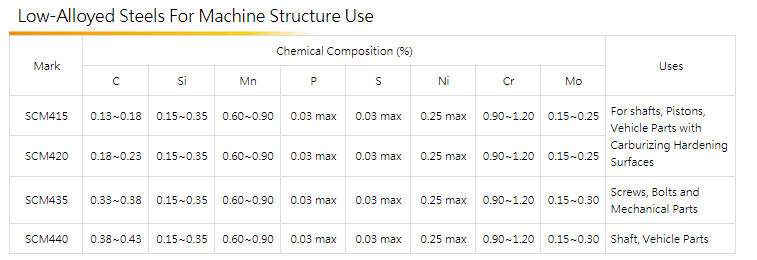

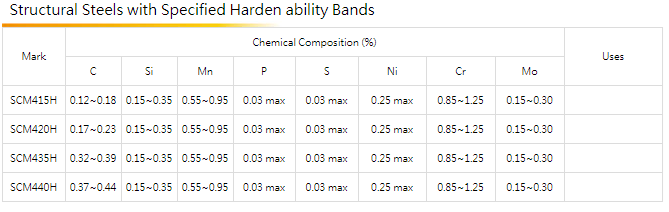

* Chemical Composition :

SCM420

SCM420H

* Mechanical properties

Tensile strength (kgf/mm²): ≧95

Elongation (%): ≧14

Cross section reduction rate (%): ≧40

Impact value (J/cm2): ≧6

Hardness (Hb) : 352~362

* Conditions of heat treatment

Annealing: 850℃ Furnace Cooling

Normalization: 850~900℃ Air Cooling

Hardening: 850~900℃ 1st Oil Cooling, 800~850℃ 2rd Oil Cooling

Tempering: 150~200℃ Air Cooling

* Criterion for heat treating conditions revise:

Ac: 770~835℃

Ar: 770~700℃

Ms: 410℃